Pigments are the coloring elements present in the paints and have a

very special place in the paint industry. The paint industry uses specialty

pigments to manufacture paints for a variety of applications. Ranging from

automobiles to buildings hardware, the list is virtually endless.

The paints that employ the wide variety of pigments can be broadly

classified according to application into two types. They are colorants for

the industrial applications and architectural/decorative applications

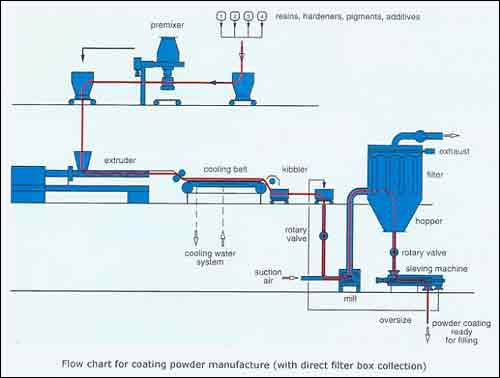

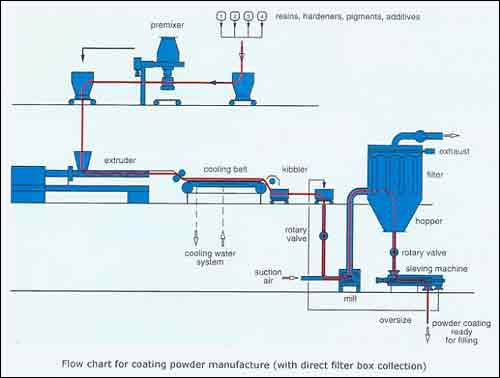

respectively. The diagram given below shows the process of use of Pigments

in manufacture of Powder Coatings:

Earth color Pigment- Derived from the

natural sources and are inorganic in nature (i.e. metal oxides). Examples:

ocher, umber, terra di siena, bolus, swedish red etc.

Earth pigments have properties like:-

- Lightfast

- Chemical

- Fast weather Resistant

Mineral Pigments- Mineral pigments comprises synthetic inorganic

pigments. Examples: chrome oxide green, titanium dioxide, iron oxide yellow,

red, brown and black, ultramarine blue, nickel-titanium yellow etc.

One of the disadvantages of mineral pigments is the toxicity and ecological

imbalance.

Plant Color Pigments- Plant colors are sourced from natural organic

pigment found in plants. Examples: indigo, alizarin red, woad, reseda,

alkanna violet and saffron.

Synthetic Pigments- Synthetic Pigments are the most widely used but

artificial organic pigments and dyes. Examples are: azo, dioxazine and

phthalocyanin.

The advantage is synthesization in almost any shade, especially in pure

color tones and gives dazzling visual effects.

More the amount of pigment and binder, better the

quality of the paint.

Paints are manufactured using 4 basic ingredient categories:

- Pigments

- Binders

- Liquids

- Additives

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry