Home Profile

Profile  Product Range

Product Range Industries

Industries Infrastructure

Infrastructure Our Quality

Our Quality Custom Manufacturing

Custom Manufacturing Network

Network Contact Us

Contact Us Send Enquiry

Send Enquiry

Woodworking Industry

Using dyes in woodworking industry is very common. From finishing for

making the stains, to toners that is applied for blending in different

species of wood, to make the unmatched colors appear uniform in the same

wood. Dyes are also added in coatings for making shading stains, that

results in color and coating in one operation. Dyes are also excellent for

preparing color touch ups. All in all, the dyes are a versatile colorant

which has the capacity to improve and enhance finishing, and restoration

operations.

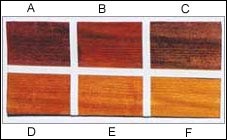

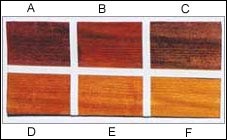

Diagram given below shows some of the most popular combinations of dye

colors that are used in furniture:

A: Red mahogany;

B: Brown mahogany;

C:Dark walnut;

D: Medium walnut;

E: Red maple;

F: Golden oak.

Tips on Selecting the Right Dye

Oil Dye- Compared to others the oil dye

is slow drying process. Although it allows more open time, but more longer

dry time is required.

Alcohol and Lacquer Dyes- These dyes are quite similar to each

other. Both has the capacity to dry exceptionally fast. This makes them very

difficult to apply by brush or wiping. They give best results when sprayed.

Any of of these dyes can be applied to coatings as a transparent shading

stain. They do not raise the wood's grain. Generally solvents for these

solubles are denatured alcohol and lacquer thinners.

Water type Dyes- It displays the best clarity and is the typically

most transparent. Among the dyes used in woodworking it is the most

colorfast. One factor that is to be considered here is that as the solvent

is water, the dyeing process is very slow. Unlike Alcohol and lacquer dyes,

they raises the wood grain.

Dye Color- It would be foolishness to judge dye colors when they are

applied, as they are very deceiving to the eye. It is seen that both the

powder and liquid stains sometimes appear as one color, but after coating,

the colors look quite different.

Color strength of Dyes- It varies from manufacturer to manufacturer.

Please be careful about the manufacturer's recommendation, to make sure as

to what ratio of dye to the solvent is the right one.

Compatability- There are now a variety of dyes that are available in

the market today. Before opting to buy any dye, it is important to determine

whether it is compatible when sealed with the coatings. Also, if it can be

added to the coating and used for making shading stains. It is also

imperative to know how the dye is applied, what solvent is used to dissolve

or dilute it and which solvent types quickens or slow down its dry time.

Powder Dyes- Can also be used along with suitable thinners.

Dyes or Pigments: The perennial dilemma

| Dyes |

Pigments |

| Dyes are very good for doing touch ups on furniture because of

transparency. Dyes do not block out the natural wood, as pigmented

colorants generally does if they are not thinned out. |

because of transparency. Dyes do not block out the natural wood, as

pigmented colorants generally does if they are not thinned out. Pigments

has its plus points too, as on some finishes, pigmented colorants are

better in matching opaque-colored finishes. Also, pigmented colorants

come up with white colors plus a plethora of other colors that can be

mixed from them. All in all, there is place in the sun for both dyes and

pigments. |

Home Profile

Profile

Product

Range

Product

Range Industries

Industries Infrastructure

Infrastructure Our

Quality

Our

Quality Custom

Manufacturing

Custom

Manufacturing Network

Network Contact

Us

Contact

Us Send

Enquiry

Send

Enquiry

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry