Carbon blacks are typically elemental Carbon that is available in

highly dispersed powdered forms. They are produced from hydrocarbons by

controlled vapour-phase pyrolysis.

Carbon Black is one of the most important types of pigments that have major

industrial applications. In Producing Carbon Black there are numerous

processes available. Mostly all the production processes depends on thermal

decomposition or incomplete burning of fuel oil or natural gas (hydro

carbons). Majority of all carbon black is made by employing the furnace

process. "Furnace black" and "channel black" are the two

very popular variants of Carbon Black. Others include acetylene black, lamp

black and thermal black. Mostly all types of Carbon blacks contain oxygen,

hydrogen, nitrogen and sulphur.

Characteristics of Carbon Black

- Average particle diameter: In most of the commercially-produced

carbon blacks the range is from 0.01 to 0.4 micrometres (µm)

- Average aggregate diameters: Ranges from 0.1- 0.8µm

- Percentage of Elemental Carbon: Between 97 to 99

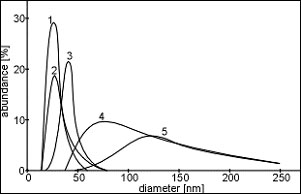

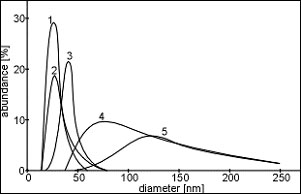

- Particle size: The following graph shows the particle size of some

carbon black pigments.

- Channel Black

- Furnace Black

- Acetylene Black

- Lamp Black

- Blacking

The requirements of applicability of Carbon Black

are critical, their importance also vary according to application. Few such

requirements are discussed here:

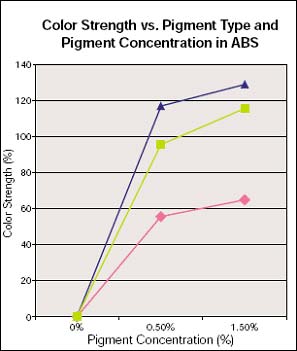

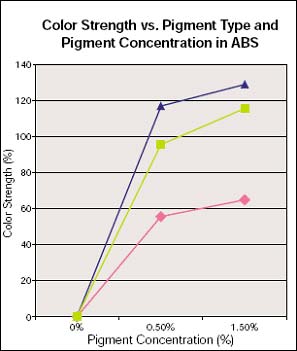

Color

Strength-

Color

Strength- Colour strength of a few type of carbon Black pigment as

appearing in Acrylonitrile butadiene styrene (ABS) polymer is shown in the

graph.

Masterbatch Dilutability- Masterbatch dilutability is approximated

and compared by the process of measuring the melt viscosity of a given

masterbatch formulation. In fact masterbatch dilutability is critical. In

the selection of the right carbon black and can result in saving substantial

formulation cost.

UV Stability- By addition of carbon black, the stability with regard

to UV rays can be increased.

Carbon Black Dispersability

Blue Tone

Carbon black is widely used into many horizons.

This include other than pigmenting, applications like UV stabilizing and as

a conductive agent in a vast number of specialty products.

Popular applications include:

Thermoplastic moulding- Some of the significant applications of

carbon black are shown here. Prominent application is found in automotive

applications.

(Steering and Dash Board system of a car using Carbon Black Pigment)

Toners and Printing Inks-

(Steering and Dash Board system of a car using Carbon Black Pigment)

Toners and Printing Inks- Carbon black enhance formulations and

offer broad flexibility in terms of specific color requirements.

Applications of carbon Blacks include Letterpress, Lithographic, gravure,

flexographic, and screen printing processes. It is important here to know

that each of these processes needs different performance attributes.

Plastics- Used in plastic masterbatch applications, like films,

conductive packaging, pipes, fibers, moldings, and semi-conductive cable

compounds.

Flexography ink- This ink is fluid, with instant drying features.

Rheology is a vital factor here. Carbon Black pigments with low oil

adsorption pigments are a must.

Offset printing- A high color strength along with high pigment

loadings, smooth flow, and a viscosity that is fairly working are needed

from the application of Carbon Black. Offset ink must not be miscible with

water. If the requirement is high gloss then lower oil absorption pigments

are required.

Coatings- Carbon blacks provide coating applications for sectors

like marine and aerospace. By way of pigmentation, conductivity and UV

protection.

Screen Printing- The critical performance factors are rheology, low

viscosity. This can be achieved by pigment blacks that has higher

structures. Optical density property can be obtained by relatively low

pigment black loadings.

Industrial Rubber Products and Tyres- Carbon black is applied for

uses like innerliners for tyres, sidewalls and treads, for industrial rubber

products, usages include belts, hoses and gaskets. In fact a majority of the

Carbon Black that is produced goes into the making of reinforcing filler for

use in tyres and other rubber article.

Carbon Black exposure can be hazardous in some

cases. Typical classes of chemicals with carcinogenic nature like polycyclic

aromatic hydrocarbons (PAHs), sulphur-containing PAHs, nitro derivatives of

PAHs are adsorbed on to surface of carbon black.

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

Color

Strength- Colour strength of a few type of carbon Black pigment as

appearing in Acrylonitrile butadiene styrene (ABS) polymer is shown in the

graph.

Color

Strength- Colour strength of a few type of carbon Black pigment as

appearing in Acrylonitrile butadiene styrene (ABS) polymer is shown in the

graph. (Steering and Dash Board system of a car using Carbon Black Pigment)

(Steering and Dash Board system of a car using Carbon Black Pigment)

![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry