Leather dyeing usually involves the use of spirit or alcohol based

dyes where alcohol quickly gets absorbed into moistened leather. Leather

dyeing formulations are similar to lacquers. They consist of a dye or

pigment, a casein or nitrocellulose resin, and a solvent.

The types of dyestuff that are used by tanneries generally varies depending

on the product range needed along with the dictates of the fashion world. It

is a fact that each tannery uses between 50-100 or more different types of

dyestuffs.

The leather industry primarily uses anionic dyestuffs, that can be

divided in the following families:

- Acid dyes

- Mordant dyes

- Direct dyes

- Basic Dyes, its use is also limited.

- Pre-metalled dyes

- Solubilised sulphur dyes

- Reactive dyes although a part of the anionic group of dyes but use

limited to a certain extent.

If we see from the chemical point of view the dyes used are mostly Azo

dyes, Anthraquinone dyes and Triphenylmethane dyes. Commercially speaking,

popular Black dyes account for nearly 60-70% of all leather dyeing. Also,

out of this a dye variety called Acid Black 210 dominates with 80-90% usage

of all of the black dyes used.

Yes! I am Interested

Applying high temperatures releases the

fat-soluble components of conventional leather dyes out of their chemical

bonds. Now these components has a tendency to migrate upwards into the

layers whose task is to give the smooth finish to leather surface. This

causes a visible change of color and intensity. What happens is that with

the rising of humidity, it is quite likely that non-permanent dyes that are

water-soluble, and low in molecular weight, will be washed out. Along with

the problems like spotting and discoloration. Also there is the risk that

migrating dye components can rub off on other materials such as plastics or

textiles.

With latest technology of dyeing leather, the development and production of

high-fastness dyes reached on top level. Now, the manufacturers get high

quality leathers for making leather products.

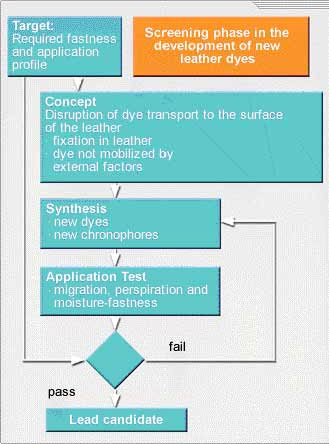

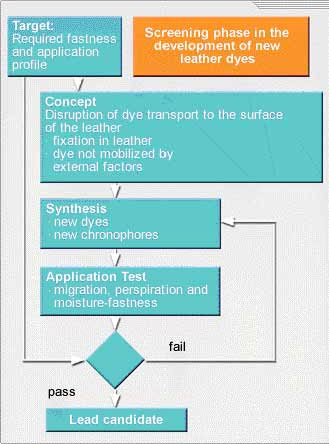

Here is a flow chart that describes the process criteria of selection of

leather dyes :

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry