Textile dyes belong to Bronze Age. If we compare this to the

21st-century, these constitute an important segment of the whole business of

specialty chemicals. Dyes that are used by the textile industry are now

mostly synthetic. They are mostly derived from two sources namely, coal tar

and petroleum-based intermediates. These dyes are marketed as powders,

granules, pastes or liquid dispersions. The concentrations of active

ingredients typically ranges from 20 to 80 percent. These are now

characterised as new dyes and are regularly developed for meeting the

demands of new technology, new kinds of fabrics, detergents, advances in

dyeing machineriest, along with overcoming the serious environmental

concerns posed by some existing dyes. Another important factor is the fact

that almost all the products are subjected to seasonal demand and variation.

Industrial textiles Dyes must rise up to meet all these new and specific

technical requirements.

With the fast changing of the product profile of the textile industry, from

high-cost cotton textiles to the durable and versatile synthetic fibres, the

pattern of consumption of these dyes is also going through rapid changes.

Now a days, Polyesters account for a major part of dye consumption.

Accordingly, disperse dyes, that is used in Polyesters, are also projected

to grow at a faster rate.

Yes! I am Interested

Classification of all the commercial textile dyes by

their generic name and chemical constitution has been done by the Color

Index (C.I.), a journal published by the Society of Dyers and Colorists

(United Kingdom) in association with the American Association of Textile

Chemists and Colorists (AATC)..

However, if we take general dye chemistry as one of the basis for

classification, textile dyestuffs can be grouped into the following

categories for an easier understanding

- Acid Dyes

- Azoic Dyes

- Basic Dyes

- Direct Dyes

- Disperse Dyes

- Reactive Dyes

- Sulphur Dyes

- Oxidation Dyes

- Mordant Dyes (Chrome Dyes)

- Optical / Fluorescent Brightener

- Solvent Dyes

- Vat Dyes

For convenience all the above dyes can be clubbed together into three

categories namely:

- Dyes for Cellulose Fibers

- Dyes for Protein Fibers

- Dyes for Synthetic Fibers

Percentage of unfixed dye for various dye types and applications

All the dyes are not fixed to the fiber during the process of dyeing. The

following Table gives the percentage of unfixed dyes for different textiles.

The reactive dye that is used for cotton shows the poorest rate of fixation.

As half of the textile-fiber market is cotton, the problems of colored

effluents stems from dyeing cotton with reactive dyes

| Fibre |

Dye Type |

Unfixed dye % |

| Wool and Nylon |

Acid dyes/ reactive dyes for wool |

7-20 |

|

Pre-metallised dyes |

2-7 |

| Cotton and viscose |

Azoic dyes |

5-10 |

|

Reactive dyes |

20-50 |

|

Direct dyes |

5-20 |

|

Pigment |

1 |

|

Vat dyes |

5-20 |

|

Sulphur Dyes |

30-40 |

| Polyester |

Disperse |

8-20 |

| Acrylic |

Modified basic |

2-3 |

![]() Profile

Profile ![]() Product Range

Product Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our Quality

Our Quality![]() Custom Manufacturing

Custom Manufacturing![]() Network

Network![]() Contact Us

Contact Us![]() Send Enquiry

Send Enquiry

![]()

A

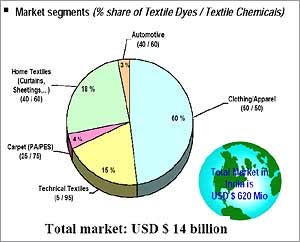

fair impression of the importance of textile dyes can be understood from

looking at the market segments, which is illustrated below:

A

fair impression of the importance of textile dyes can be understood from

looking at the market segments, which is illustrated below:![]() Profile

Profile

![]() Product

Range

Product

Range![]() Industries

Industries![]() Infrastructure

Infrastructure![]() Our

Quality

Our

Quality![]() Custom

Manufacturing

Custom

Manufacturing![]() Network

Network![]() Contact

Us

Contact

Us![]() Send

Enquiry

Send

Enquiry